our services

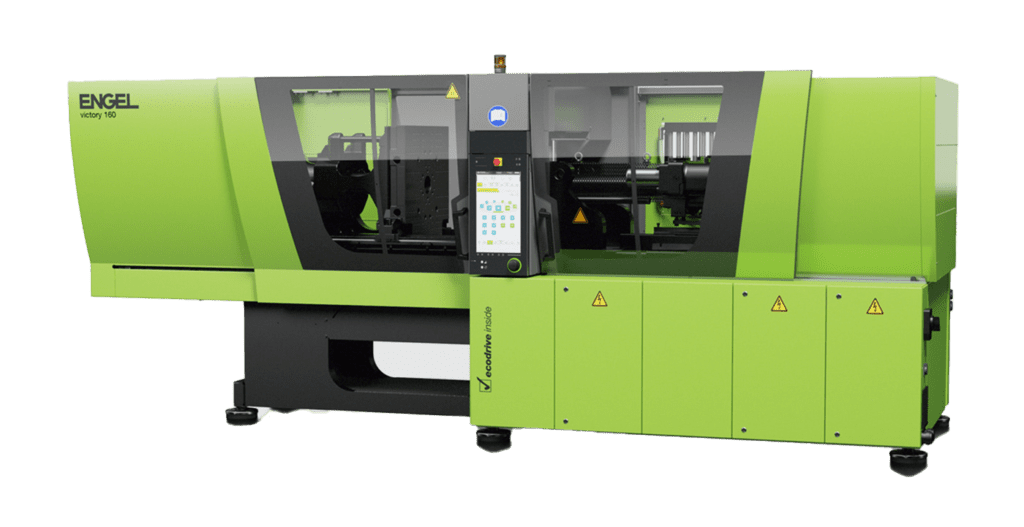

Injection Moulding

We offer design and manufacture of complex injection moulding tools with complete in-house mould flow analysis and trial run reports.

We can also accommodate and assist you as you transition from low to large volume production.

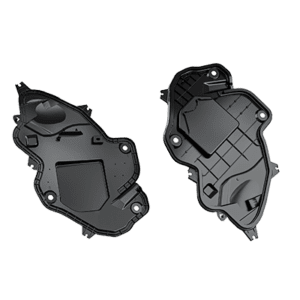

Plastic moulds

Steel or Aluminium moulds

2K (two different materials in one part) moulds

3K (three different materials in one part) moulds

LSR (Liquid Silicone Rubber) moulds

Insert moulds

Production volumes: low – 1,000,000+

Plastic Injection moulding

Ideal for large-scale manufacturing with consistent results across various plastic components.

2k / 3k Injection Moulding

For more complex designs, 3K options blend three materials for superior versatility and durability.

(MIM) Injection Moulding

Ideal for industries needing durable, intricate metal parts in large volumes, like automotive and aerospace.

(LSR) Injection Moulding

Perfect for high-performance applications, it ensures durable, biocompatible components, ideal for automotive, medical and domestic consumer products.

Industries

Injection moulding is a cost-effective manufacturing process used in automotive, medical, electronics and consumer industries, producing precise repeatable, high-volume parts with minimal waste and a wide range of material options.

Contact Us

Experience the seamless integration of cutting-edge manufacturing capabilities.

Embark with us today on our journey to redefine innovation and manufacturing.