our services

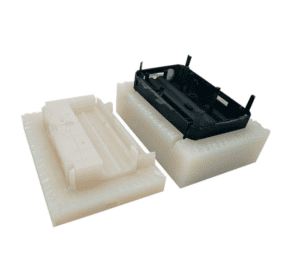

Vacuum Casting

Vacuum casting is a fast and cost effective technique for producing high-quality plastic parts for the functional testing of prototypes or low-volume series production.

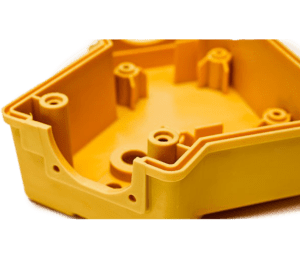

The perfect interim solution between prototype and full production producing 100+ parts per day.

Materials available:

PMMA | ABS | PP | PC | PA | PU | SHORE rated Rubber and Silicone

Thickness of workpieces:

Minimum 0.5mm Optimum 1.5 mm up to 5 mm

Large Volume capabilities up to 2m x 1m x 0.6m

Plastic vacuum Casting

Using silicone moulds and a range of materials, it delivers high tolerance durable components with excellent surface finish.

Liquid Silicone vacuum Casting

Perfect for prototyping and small-batch runs, it ensures consistent quality and performance across a range of SHORE rated rubber and silicone-based products.

Metal vacuum Casting

This technique enhances precision, reduces air pockets, whilst producing high-quality components with intricate details and superior finishes.

Vacuum Die Casting

Industries

Vacuum casting is widely used in the domestic and leisure industries as well as commercial settings for small volume production runs. 3D Prints can now be used as patterns for a quicker more cost effective turn-around and route to market.

Contact Us

Experience the seamless integration of cutting-edge manufacturing capabilities.

Embark with us today on our journey to redefine innovation and manufacturing.